injection moulding ppt

Injection moulding can be performed with a host of materials including metals glasses elastomers confections and most commonly thermoplastic and thermosetting polymers. The mold is made from metal usually either steel or aluminium widely used for manufacturing a variety of parts from the smallest component to entire body panels of cars.

Injection Moulding Technique Presentation

Closes the Mould for further cycle.

. Injection Molding AP Lee Kim Seng Injection molding technology is a method of processing predominantly used for thermoplastic polymers. Controlled by shrinkage and warping. PowerPoint Presentation Plastic Injection Molding Nachiket Kulkarni 12082016 Introduction Various optical technologies have plastic components Injection molding can achieve mass production Producing components with machining process may be expensive Economical Plastic is an alternative to glass Limited by physical properties.

A thin plastic skin forms and solidifies in the mold wall. This will minimize part distortion by facilitating even cooling throughout the part. ALOK RANJAN Document presentation format.

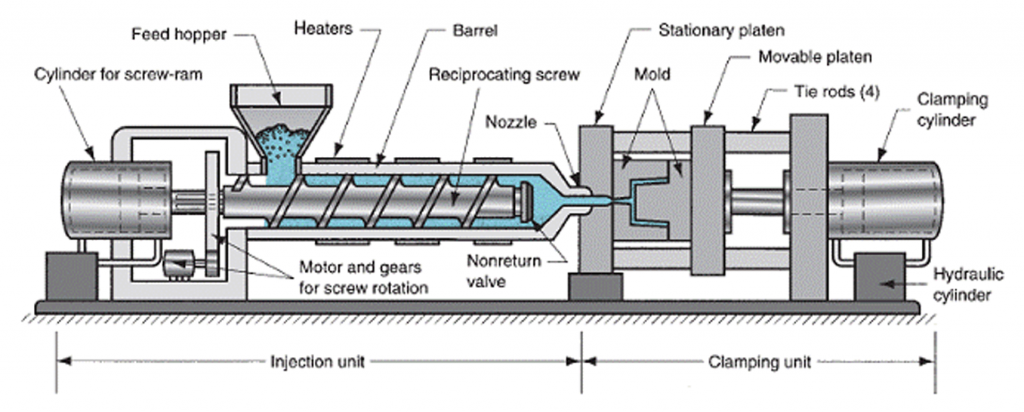

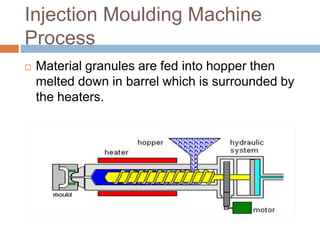

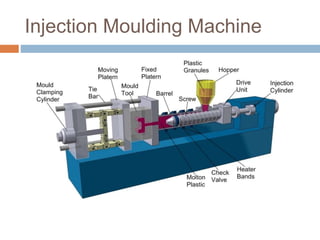

Injection Molding 11 Injection machine The injection machine is a machine that melt plasticize the molding material inside the heating cylinder and inject this into the mold tool to create the molded product by solidifying inside it. Ejection points Plastic must be ejected square to the mould Tapered sides Tapered sides allows the product to be removed from the mould. It consists of heating thermoplastic material until it melts then forcing this into melted plastic into a steel mold where it cools and solidifies.

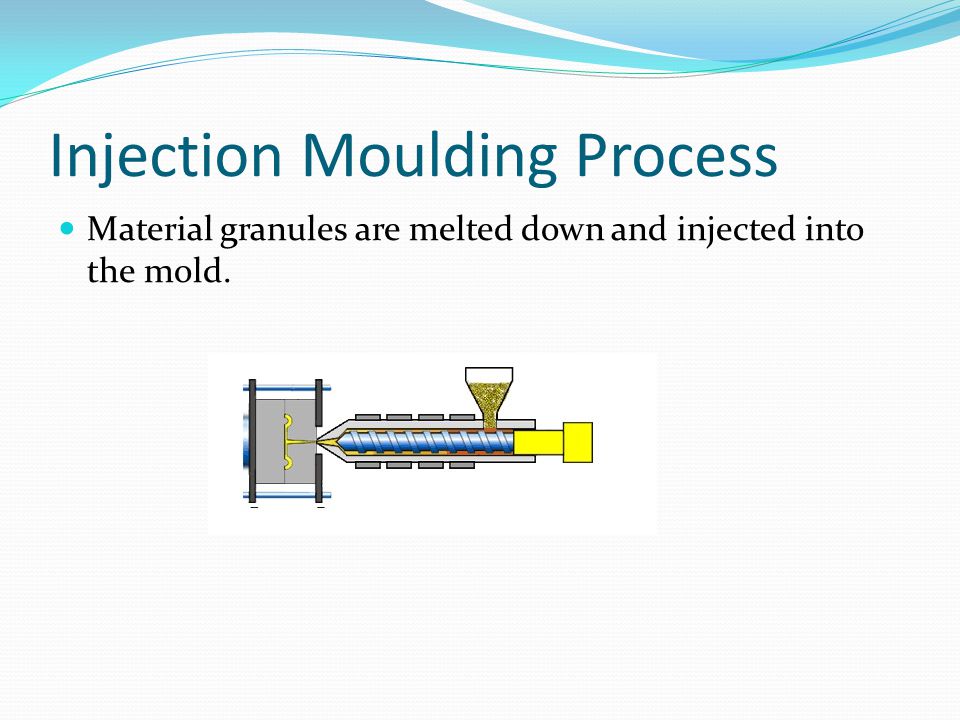

A plastic material usually called a resin is melted and forced into a mould via injectionThe mould which usually comprises two or more pieces depending on its. Injection molding is a manufacturing process for producing parts by injecting material into a mould. Granulated or powdered thermoplastic material is heated melted and then forced under pressure into a mould.

Inserting a small amount of nitrogen or chemical blow agent into the plastic material makes the walls thicker. THERMOSET INJECTION MOLDING Last modified by. Plastics are by far the most common materials that are produced using injection moulding.

On-screen Show 43 Other titles. The increasing sophisticated use of injection. Foaming happens as the melted plastic material enters the mold cavity.

Refills the material for the next cycle. There are several different types including injection extrusion and stretch blow moulding. Hence polymer fillers mold geometry and processing conditions can all influence the final tolerance.

Plastic injection molding is a manufacturing technique for making parts from thermoplastic and thermoset materials in contrast to the extrusion which makes continuous parts of constant cross section injection molding make discrete parts with complex and variable cross section molten plastic is injected at high pressure into a mold. Once in the mould the material cools forming a component that takes on the shape of the mould cavity. Injection moulding is a highly automated production process for producing large quantities of identical items.

Shrinkage is of order 10-1001000 for unfilled and 1-101000 for filled across the thickness 29 Where is injection molding. Blow Molding Modified extrusion and injection-molding process Characteristics Hollow thin-walled parts of various sizes High production. Design Guideline for Injection Molding Components General accepted design guidelines.

MOULDING note ppt for study purpose. Injection moulding is a manufacturing process that allows for parts to be produced in large volumes. Detail on Side External Thread TYPES OF UNDERCUT EXTERNAL UNDERCUT It can be removed by Side core actuated by mechanical pins Hydrolic Phumatic cylinders.

Hydraulic pressure - Specific injection pressure Typical 360 ton moulding machine Specific pressure in front off the screw bar psi 2100 2055 1800 25000 1510 1500 20000 70 dia 276 inscrew 1200 1155 15000 60 dia 236inscrew 80 dia 315 inscrew 10000 600 5000 300 0 30 60 90 120 150 bar Reading at pressure gauge. Where is injection molding. The process is simple in principle.

Injection moulding can be performed with a host of materials mainly including metals glasses elastomers confections and most commonly thermoplastic and thermosetting polymers. Injects the molten material to a closed mouldvia a channel system of gates and runners. Close dimensional tolerances can be maintained.

What Is Injection Moulding. Advantages of Injection Moulding Process Minimal scrap loss result as runners gates and rejects can be reground and reused. Injection moulding is the primary method for creating plastic parts components and products.

Parts can be moulded with metallic and non-metallic inserts. It works by injecting molten materials into a mould or mold in the United States. PowerPoint Presentation Injection Moulding Injection point The point where the plastic entered the mould.

Injection moulding is a manufacturing process for producing parts by injecting material into a mould. Times New Roman Arial Wingdings Calibri Verdana Sunny Days 1_Sunny Days INJECTION MOLDING OF THERMOSET PLASTICS THERMOSET INJECTION MOLDING MACHINE PHOTO OF PLASTICIZING THE RESIN PHOTO. The Blow Moulding Process - Plastic Moulding 2017-3-31 The blow moulding process in comparison with injection moulding is a low pressure process with typical blow air pressures around 25 to 150 psi.

It is typically used as a mass production process to manufacture thousands of identical items. Injection molding make discrete parts with complex and variable cross section Molten plastic is injected at high pressure into a mold which is the inverse of the desired shape. Machine operation sequenceThe mould closes and.

PowerPoint PPT presentation. Same items can be moulded in different materials without changing the machine or mould in some cases. Choose the material and the main wall thickness for minimum cost.

Design the main wall of uniform thickness with adequate tapers or draft for easy release from the mold.

Plastic Injection Molding Machine Ppt Video Online Download

The 5 Keys Stages Of Plastic Injection Or Injection Molding

Key Benefits Of The Structural Foam Injection Molding Process Authorstream

Injection Moulding Technique Presentation

The Plastic Injection Moulding Process Youtube

3 Basic Steps Of The Injection Molding Process Injection Moulding World Magazine

Why Choose Injection Moulding Geomiq

Injection Molding Process Xcentric Mold Engineering

Aclaryn Plastics Injection Moulding Process Plastic Moulding Injection Moulding

The Outline Of Injection Molding

Comments

Post a Comment